Sustainable and innovative

HYPROSYN® technology

HYPROSYN® is the name of the "hydrogen-peroxide-to-propylene-glycol" (HPPG) process. It stands for the direct synthesis of propylene glycol — a highly in-demand product for many industries — from hydrogen peroxide. This efficient, more sustainable technology was developed by Evonik in collaboration with Dow.

Propylene glycol markets

The demand for propylene glycol is huge, and it’s growing by 2.5 percent annually. The compound is used for example in antifreeze, lubricants, fiberglass-reinforced plastics, cleaning and washing products, and latex wall paints.

It’s also indispensable for the food industry, giving chewing gum the right consistency, making baked goods soft, and keeping packaged foods moist. Livestock farmers use it to treat metabolic disorders in their dairy cows. Today, about two million tons of propylene glycol are processed annually worldwide. In order to meet the growing demand, developers have been working for years to find more efficient and environmentally friendly solutions for producing propylene glycol.

Production of propylene glycol

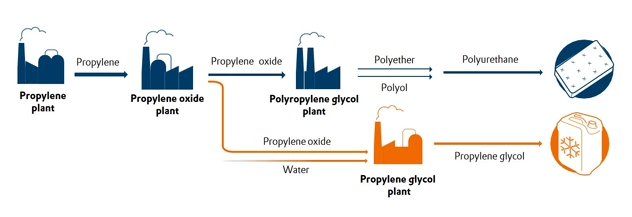

Previously, the first step in the production of propylene glycol had often been the production of propylene oxide. The intermediate product propylene oxide is in high demand. One-fifth of the total production volume worldwide of propylene oxide is used to synthesize propylene glycol.

One way to continue meeting this demand in the future would be to build additional propylene oxide production plants. However, each of these plants would cost hundreds of millions of euros. Alternatively, researchers could search for innovative solutions that simultaneously open up new applications for environmentally friendly hydrogen peroxide.

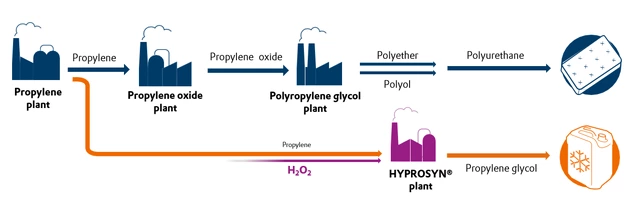

Thus, the HPPG process — under the brand name HYPROSYN® — was born. Evonik and Dow collaborated to develop a propylene glycol production method that can synthesize this highly in-demand product directly from hydrogen peroxide. This skips the step of first producing propylene oxide as an intermediate.

As a result, the HYPROSYN® process is not only more cost-efficient than the previously used technology; it also makes a significantly higher yield possible while requiring much less energy. As with HPPO synthesis, except for water there are no other co-products that would have to be separated out. Now that the process has functioned superbly in the laboratory, it is being scaled up in a pilot plant with a capacity that is 80 times bigger.

A new life for old plants

For the production of propylene glycol propylene oxide is needed as an intermediate.

The chemical reaction of propylene and hydrogen peroxide takes place in one single reactor thanks to the HYPROSYN® technology.

Benefits of the HYPROSYN® process

But the advantages of this new process go even further. That’s because the chemical reaction of propylene and hydrogen peroxide that has just been described takes place in one single reactor. That makes the previous precursor product, propylene oxide, unnecessary. Through the economical conversion of existing propylene glycol production plants to HYPROSYN® production, the propylene oxide that was previously needed can now also be used as a basic material for PU products.

The new technology can thus be regarded as a smart method for indirectly expanding the capacity of propylene oxide production plants. In addition, the introduction of HYPROSYN® technology makes it possible to manage the production of propylene glycol and of propylene oxide independently of each other. As a result, the production volumes of these two materials can be more easily adapted to the demand.

Evonik is now working together with Dow to refine the new technology to the point of market maturity. The U.S.-based company Dow produces propylene glycol and propylene oxide in many plants on four continents and is the global market leader for both products.